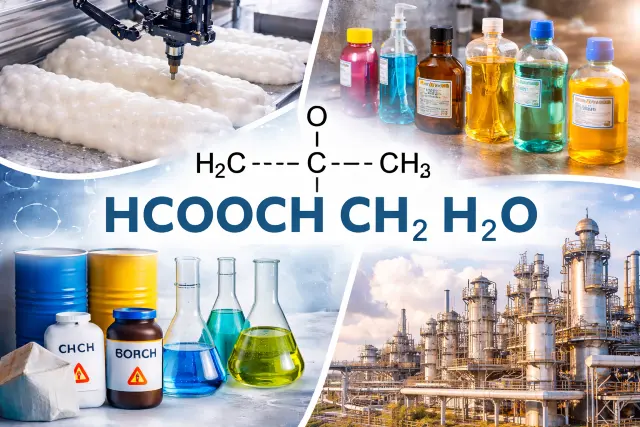

If you have been seeing HCOOCH CH2 H2O trending in searches, notes, or chemistry discussions, you are not alone. The phrase looks like a “formula,” but in practice it is often used online as shorthand for formate ester chemistry involving a CH2 unit and water, especially reactions where a formate ester meets H2O (hydrolysis) or where formate fragments show up in manufacturing pathways. In plain terms, people are usually trying to understand how HCOOCH CH2 H2O connects to real industrial chemicals such as methyl formate, formic acid, and methanol, and why manufacturers care.

This article breaks down what HCOOCH CH2 H2O commonly points to, and then focuses on what you came for: real world uses in industry and manufacturing, from polyurethane foam to solvent systems and chemical intermediates.

What does HCOOCH CH2 H2O usually mean in practical chemistry?

You will find HCOOCH CH2 H2O written in different ways across the web, and that is part of the confusion. In formal chemistry, you would normally see a specific molecule written clearly (example: HCOOCH3 for methyl formate) or a complete reaction equation. But in many educational or “viral chemistry” contexts, HCOOCH CH2 H2O is used as a compact way to indicate:

- A formate ester fragment (HCOO–) attached to carbon

- A methylene unit (CH2) as part of the carbon chain

- Water (H2O) as a reactant, often implying hydrolysis or water participation

One of the most common “real” industrial anchors for this topic is methyl formate, a major C1 chemical intermediate used to produce multiple industrial chemicals and also used directly in some manufacturing applications.

Why manufacturers care about this chemistry

Industry does not care about internet shorthand. It cares about outcomes:

- Can the chemistry be scaled safely?

- Is the feedstock available and cost stable?

- Does it reduce environmental impact or replace older compounds?

- Does it enable faster, cleaner production?

Methyl formate is frequently discussed as an industrial intermediate and is used to make other chemicals (including formamide and dimethylformamide) and can function as a blowing agent in polyurethane foam applications.

That is the bridge: HCOOCH CH2 H2O often leads people toward formate ester chemistry, and formate esters lead manufacturers toward feedstocks and intermediates used across materials, coatings, foams, and synthesis pipelines.

Industrial use #1: Chemical intermediate for high value manufacturing

This is the biggest bucket, and it is where the money is.

Methyl formate as a “hub” intermediate

Industrial suppliers and technical references describe methyl formate as a significant intermediate in C1 chemistry, used to produce or support production of multiple downstream chemicals, including methanamide (formamide) and N,N-dimethylformamide (DMF), along with other industrial products.

Why this matters in manufacturing:

- DMF is widely used as an industrial solvent in polymer processing and chemical synthesis.

- Formamide is used as a chemical intermediate and solvent in industrial contexts.

- Formate chemistry supports pathways that connect simple feedstocks to more complex, high-margin molecules.

What “CH2” can imply in production pathways

The “CH2” piece in the keyword often shows up when people are discussing reactions that move from C1 intermediates into C2 building blocks or derivatives (for example, pathways that mention glycolates, ethylene glycol related derivatives, or other two-carbon structures). Some supplier documentation lists methyl formate as being used in routes toward products that include methyl glycolate and ethylene glycol related chemistry.

Industrial use #2: Polyurethane foams and blowing agent applications

One of the most practical, factory-floor uses linked to formate ester chemistry is polyurethane foam manufacturing.

Why blowing agents matter

Blowing agents create the cellular structure in foam. Different blowing agents affect:

- Foam density

- Thermal insulation performance

- Dimensional stability

- Process safety and emissions profile

Methyl formate in foam systems

Technical and policy documents have assessed methyl formate as a blowing agent option in polyurethane system manufacturing, including demonstration and feasibility assessment work.

In practical terms, methyl formate is appealing here because it can function as a blowing agent in specific polyurethane applications, and it is often discussed in the context of replacing older blowing agent families.

Industrial use #3: Solvent and quick drying applications

Solvents are not glamorous, but they are everywhere in manufacturing.

Where formate esters show up as solvents

Methyl formate is referenced as a solvent for certain coating and polymer related materials and as a quick drying option in some contexts due to its volatility characteristics.

Typical manufacturing areas where solvent performance matters:

- Coatings and finishes

- Resin and polymer processing

- Specialty chemical formulation

- Cleaning steps in controlled production lines (where permitted and regulated)

Important detail: industrial solvent choice is always governed by safety, emissions rules, compatibility with materials, and the plant’s handling systems. When manufacturers pick a solvent, it is rarely about “does it dissolve,” and more about “does it dissolve safely and consistently at scale.”

Industrial use #4: Producing formic acid for textiles, leather, rubber, and more

If HCOOCH CH2 H2O leads you into hydrolysis discussions, you quickly meet formic acid, which is a workhorse chemical in multiple industries.

Why formic acid is in high demand

Formic acid is used in industrial applications including:

- Textile finishing and dyeing processes

- Leather tanning and processing

- Rubber processing and latex coagulation

- Chemical manufacturing as an intermediate

These application areas are repeatedly cited in industrial discussions of formic acid’s value chain.

So the manufacturing relevance is straightforward:

- Formate ester pathways can connect to formic acid supply

- Formic acid supports several large industrial sectors

Industrial use #5: Methanol as a feedstock for major manufacturing chains

Another common destination from formate ester plus water chemistry is methanol. You see methanol everywhere because it is one of the big platform chemicals.

A major review paper describes methanol as a core building block used to create a wide range of commercial products, and notes that a large share of methanol goes into producing other chemicals such as formaldehyde and acetic acid, which then feed into plastics and many industrial materials.

That is why manufacturers care:

- Methanol routes into formaldehyde and acetic acid

- Those route into resins, plastics, and industrial materials

- Demand is tied to industrial growth and supply chain stability

How HCOOCH CH2 H2O fits into real manufacturing decisions

This is the part most articles skip. In real plants, the question is not “what is the formula.” It is:

1) Process economics

- Feedstock cost and availability

- Yield and selectivity

- Catalyst performance and longevity

Methyl formate industrial production is commonly associated with carbonylation type manufacturing routes rather than only lab esterification, and water sensitivity and dryness can matter in certain catalyst systems.

2) Safety and handling

Formate esters and methanol related chemicals can be flammable and require strict handling controls. Manufacturers rely on SDS guidance, plant procedures, and regulatory requirements, not internet recipes.

3) Environmental and compliance pressure

Blowing agent selection and solvent selection are heavily shaped by:

- Emissions rules

- Worker exposure rules

- Waste and discharge rules

- Corporate sustainability targets

That is why methyl formate is often discussed in industrial foam contexts and modern process choices.

Real world examples by industry (quick mapping)

Here is a practical “where it shows up” mapping so the topic feels less abstract.

Manufacturing sectors linked to this chemistry

- Foam manufacturing: methyl formate in certain polyurethane blowing agent systems

- Chemical production: methyl formate as an intermediate toward DMF, formamide, and other chemicals

- Textiles and leather: formic acid in processing and finishing

- Plastics and resins supply chains: methanol feeding formaldehyde and acetic acid value chains

- Coatings and specialty formulation: solvent and quick-dry roles discussed for methyl formate

Common questions people ask about HCOOCH CH2 H2O

Is HCOOCH CH2 H2O a single compound?

In many cases, it is not written like a strict chemical name. It is often shorthand that points toward formate ester plus water chemistry, and the industrial discussion often lands on methyl formate and its downstream products.

Why is water (H2O) important in these reactions?

Water is commonly associated with hydrolysis and with process sensitivity in industrial catalyst systems. In production, controlling water can affect reaction rate, selectivity, and catalyst performance.

What is the biggest industrial “use” connected to this topic?

The largest practical connection is usually methyl formate’s role as an intermediate and its use in foam blowing systems, plus the downstream importance of methanol and formic acid in manufacturing.

Conclusion: why HCOOCH CH2 H2O matters outside the textbook

The keyword HCOOCH CH2 H2O might look like a confusing string at first, but the industrial story behind it is actually simple: it often points toward formate ester chemistry, where compounds such as methyl formate act as production hubs, feeding manufacturing routes into solvents and intermediates, polyurethane foam processing, and the broader supply chains for formic acid and methanol. Once you see those connections, the topic stops being “just chemistry” and starts looking like what it really is: a set of reactions and materials that quietly support modern manufacturing.

If you want to understand the industrial backbone behind this topic, it helps to read about methyl formate itself, because it connects directly to multiple downstream manufacturing applications.